Subcontractor Management for Engineering Companies

Follow these tips to help streamline subcontractor management for engineering companies and prevent unnecessary complications throughout daily operations.

Follow these tips to help streamline subcontractor management for engineering companies and prevent unnecessary complications throughout daily operations.

Table of Content

Subcontracting in the A&E industry has greatly increased in recent years. Technology, size, and scale of projects are tending to be larger and more complex. As a result, many firms subcontract work because of insufficient resources or expertise in a specific area. For firms working in the government arena, contracts may require a certain participation rate of MBE, WBE or other partners with disadvantaged business status.

Since the performance level of sub-contractors is a reflection of the company that hired them, it’s critical to effectively manage them throughout the course of daily operations until a project is complete. Following these tips should help streamline this process and prevent unnecessary complications.

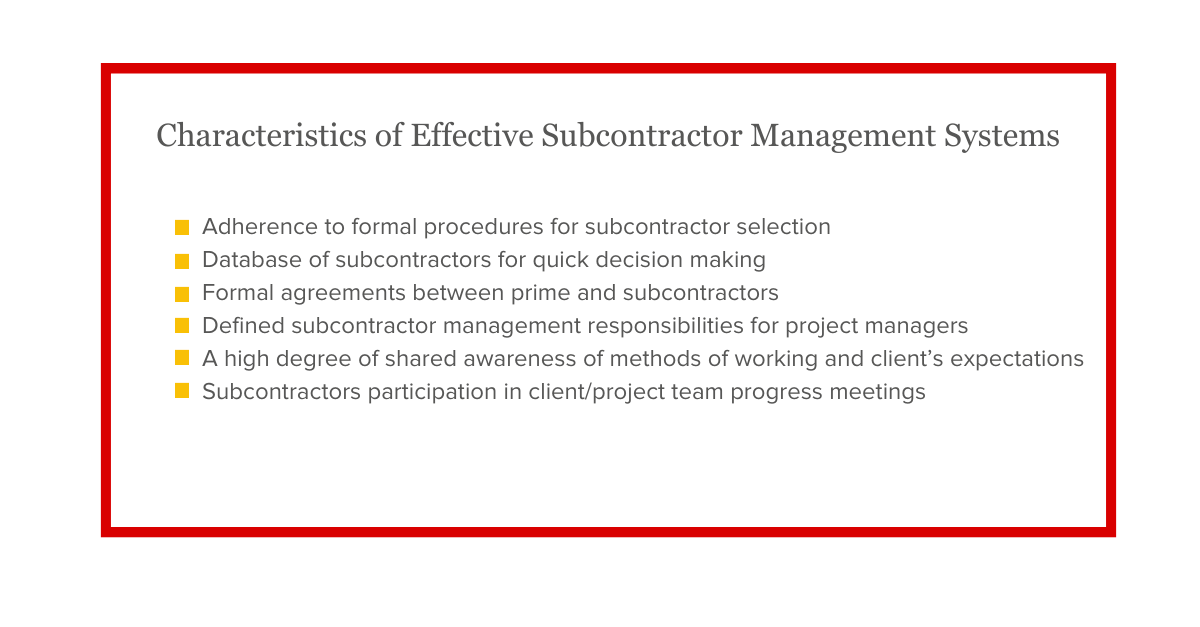

Most firms take great care to make certain that their subcontractors have the necessary skills to perform the tasks contractually required. However, fewer have formal processes for evaluating their business relationship with their subcontractors.

Some of the top challenges with subcontracting include relationships between prime and subcontractors being largely informal and/or bias in subcontractor selection based on existing relationships with either members of the firm or customer personnel. For this reason, it is important to have a formal procurement standard for subcontractors so you can make decisions easier and faster whether or not they are qualified to provide the services required. Many companies achieve this through a prequalification process whereby they develop a database of qualified sub-contractors in advance of any specific project need. By establishing a subcontractor database, firms are able to know all the pertinent information about subcontractors including performance assessments, specialties, geographic reach, and customer connections.

Through a pre-qualification process, you can also identify red flags that could indicate a subcontractor is not up for the job or poses undo risk for your company, including refusal to provide financial statements or poor presentation of financial statements, lack of financial strength, a history of performance problems or claims, limited or no prior work history in the discipline and/or no or limited experience in the geographic area. In addition to company information, it is useful to learn more about the personnel who may be an assigned to your project. Consider reviewing resumes on project managers, project engineers and staff. If certain key personnel are clearly superior to others, try to negotiate their involvement as part of your contract.

Some key best practices when establishing a formal pre-qualification process include:

When margins are tight and the opportunity to raise prices is limited, managing the cost of subcontracted labor is the only way to remain profitable. Managing subcontracted labor cost is handled the same as your other costs – know your ratios.

By comparing the ratios for the past several years, you can determine whether your cost of subcontracted labor has been increasing, decreasing, or staying the same over that period of time. This sort of trend analysis is helpful when negotiating prices with your subs going into new projects and making the sort of decisions that will help improve your financial performance. Subcontracted Labor Cost Ratio. This simple ratio can help you get started. It is calculated by determining the total amount spent during a specific period on all subcontractors and dividing that number by total revenue from those jobs.

Best practices clearly indicate that the most critical phase of the subcontracting process is the Planning phase. Cost overruns, schedule delays, technical failures, regulatory and statutory noncompliance, legal disputes, termination, claims, and customer dissatisfaction are but a few of the results of poor planning. Prior to beginning a project, it’s usually best to arrange a meeting with a sub-contractor. This is the time to discuss the plans, go over costs, expectations and deadlines. Doing so should ensure that both parties are on the same page, and it’s a perfect time to ask questions and get feedback.

Although this is important for any project, it’s particularly crucial if it’s the first time a company has worked with a sub-contractor. Along with this, having a sub-contractor sign a contract before they are paid is a good idea. Doing so will hold them accountable for having a job done correctly and on time. Contracts should include specifics such as critical work processes, the delivery schedule, deliverables and costs.

Some key elements for subcontractor contracts include:

Communication is key part of being successful, so this should be maintained throughout a project’s duration. Having open communication is critical in case adjustments need to be made and to provide feedback. Otherwise, a miscommunication can be detrimental to a project and thwart its progress. At a minimum, the project manager should be able to quickly reach subcontractors via telephone or email and vice versa without any delays if need be.

Better yet using a project collaboration tool to help the entire team organize their work and work product, including file sharing, project planning/management, group calendaring, and event scheduling, is particularly beneficial for projects with a distributed workforce. Collaboration tools offer a wide variety of benefits, ranging from cost reductions to increased innovation to improved quality.

Here are a few key ongoing communications needs to consider:

To improve the likelihood that deadlines are met, a shared project management tool with real-time data is the best option. You can monitor projects from conception to completion and ensure that sub-contractors are keeping up with their tasks. By maintaining accurate records with real time inputs from the team, you will know how much progress has been made and how it compares to initial expectations.

This type of software will simplify billing and help you stay on top of your finances with greater ease. You can also create reports to properly document the data you accrue. You may even want to email relevant information to sub-contractors every few days or so to keep everyone on the same page.

Some key best practices in subcontractor oversight:

Subcontracting work to qualified partners continues to be an effective strategy for companies who have insufficient resources or expertise in a specific area. With best practices employed, the challenges and common mistakes that plague many firms can be avoided. Instituting sound subcontractor management strategies can have a positive impact on your customer relationships and your bottom line.

If you have questions about solutions for managing subcontractor management, call one our AEC experts today.